Ria Patel

UKIMEA Press Office,London

Ria Patel

UKIMEA Press Office,London

Arup and EnerMech’s digitised structural integrity inspection on the Beryl Alpha platform has led to a significant saving in operational costs, risk and time offshore for Apache North Sea LLC.

The Beryl Alpha owned by Apache is one of the largest offshore platforms in the world, situated in the North Sea. Requiring thorough and frequent safety inspections, Apache commissioned Arup and inspection specialists EnerMech to undertake a digital approach for the routine structural integrity inspection utilising Arup Inspect 3D™ to undertake the structural integrity inspection

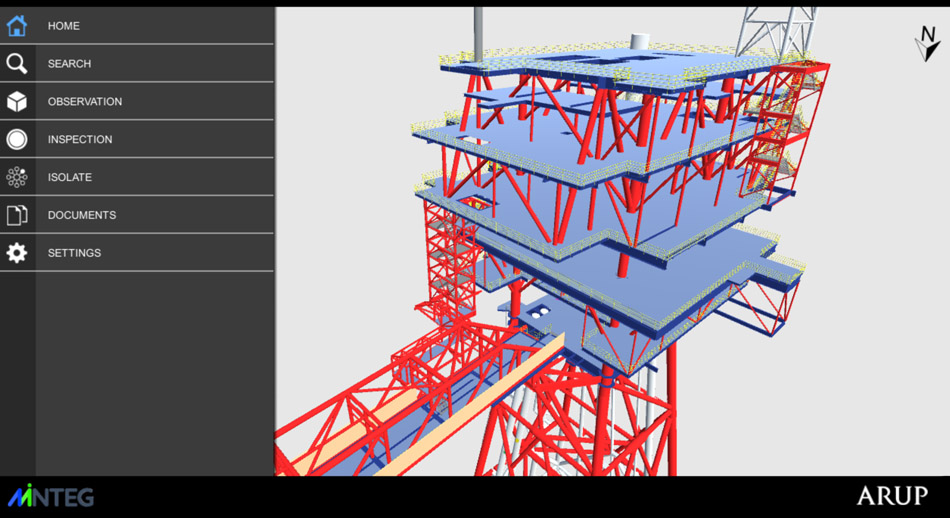

The innovative Arup Inspect 3D digital service replaces high risk offshore working at height inspection methods with the application of remote visual inspection tools. It also enables operators and asset owners to access their interactive inspection data 24/7 and make informed decisions about asset repair, replacements or improvements.

Arup and EnerMech worked to create a baseline geometric digital twin of the platform to sufficiently capture inspection data. Over 60,000 images, including 360° panoramic views, captured ultra-high-resolution inspection data. These enhanced records contributed to improved reporting reliability and the 3D model-based tablet application, which will help Apache on its journey to adopting a digital approach for the platform.