The use of robots continues to spread across industry. Sophisticated, fixed-arm robots have been assembling cars on production lines for decades. Today robots are gaining bigger and bigger roles in healthcare, mining and other manufacturing sectors.

Construction however has been slow to adopt robot workers. A few, static, fixed-arm robots have slowly been introduced into the construction process on small scale projects and pavilion type buildings. But these are limited to what they can construct by the length of their arms and their fixed position. The sheer variety and nature of construction sites requires a more flexible, dynamic and responsive solution. One emerging possibility is cable robots.

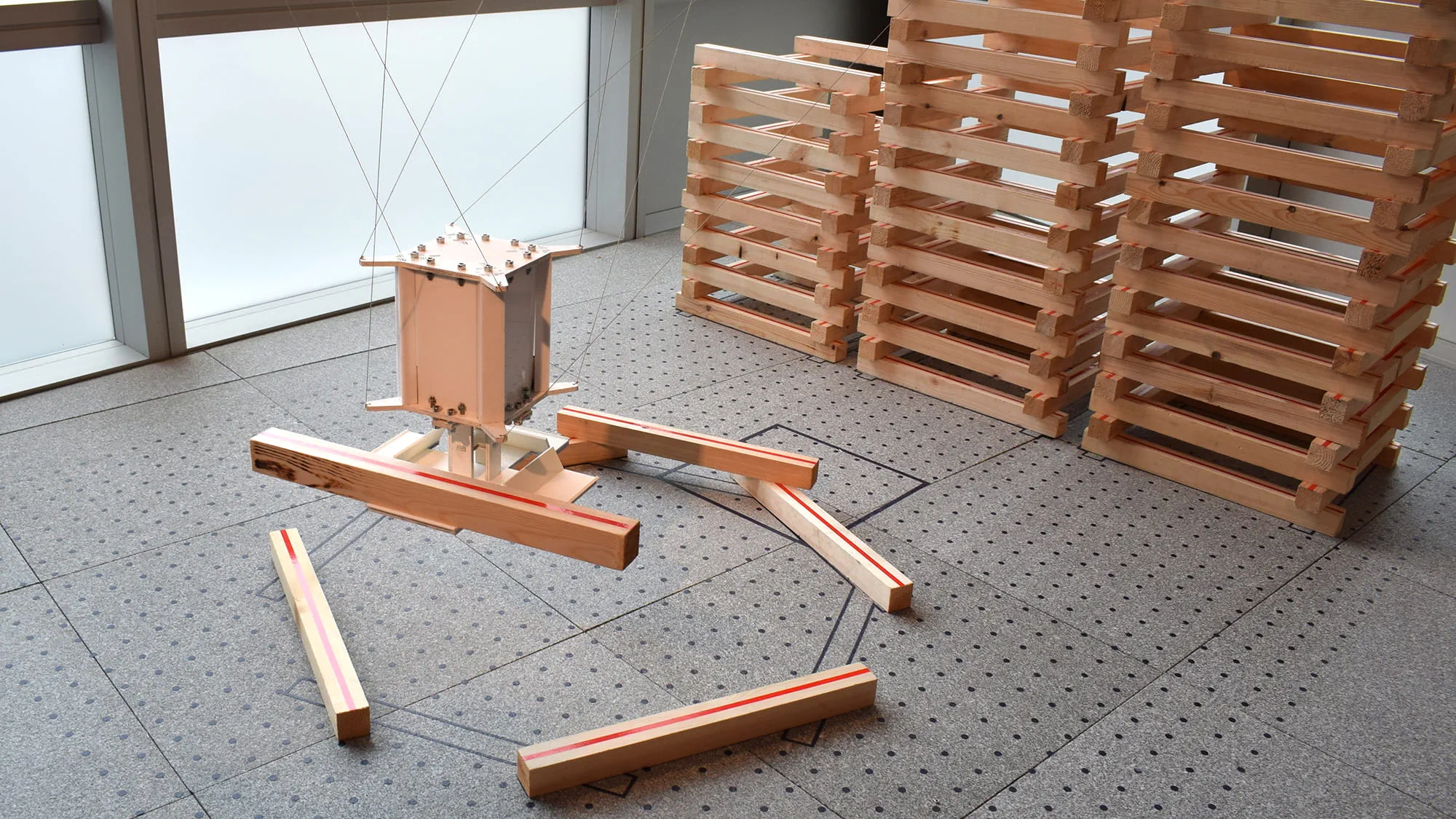

Cable robots are highly flexible, easy to install and able to move precisely in three dimensions. They typically comprise a central lifting device suspended from a number of cables and winches. A cable robot can be programmed to select, lift and move construction elements into a predetermined position based on x, y, z coordinates, having scanned their environment to calibrate their exact position in space. By using winches to change the length of the supporting cables the lifting arm would be able to move in all directions.

“Viewing construction as the assembly of ‘off-site’ fabricated building components is slowly becoming the norm, but we haven’t yet brought the advantages of digital tools and automation to the site itself. ”

Francis Archer Project Director, Arup

The robot advantage

Cable robots’ advantage over the fixed-arm ones you find on production lines, comes from the wide range of locations they can operate in. On a construction site, they could be attached to adjacent buildings rather than having to install huge tower crane-like structures. Previously difficult construction sites would become accessible using simple support structures that place the winches at any height and in any position.

Once installed the cable robot assembler won’t suffer from fatigue or tiredness so could theoretically run day and night, far more safely than a human operated tower crane. The small amount of noise generated from the winch motors and the movement of the end effector is significantly less than a traditional building site allowing it to be run at night.

The winning entry for 2017 annual competition No.8@Arup is a perfect illustration of how the construction industry will evolve and embrace the potential that machine learning has to offer. Watch the video below to see how collaboration amongst emerging designers, across all sectors and disciplines can lead to an exploration of new technologies and techniques.

What could a robot build?

So how could cable robots take part in construction? Robotic automation works best when carrying out repeat, similar tasks. This means buildings will need to be designed as a set of components that can more easily be assembled and connected. These components will need to be designed with simple, rigid connections that snap together or interlock to allow them to be assembled in a pre-determined sequence with minimal human interaction.

Some building typologies are more suitable to cable robot construction than others. Buildings that involve many repeat components or have vertically repeatable floor plates would all benefit, possibly skyscrapers or modular housing. Architects and engineers would still be able to program the variances or differences between the design solutions so that a measure of design individuality is retained.

There would be implications for delivery and storage too, with components brought to site and stacked in ordered, individual piles. The robot will need to know where to pick up the correct component from the right pile and in the right order. The stacking order of the components in the piles becomes just as important as construction sequence itself.

Changing an industry

Bringing cable robots into construction could result in dramatic improvements to an industry used to incremental change. Safer, automated construction sites will speed up the time taken to erect buildings, and lower the impact on the neighbouring community. Building costs could come down too, given the reduced time on site and labour cost savings. But we should be clear: this will require a fundamental shift in how we, as architects, designers and engineers design and ultimately construct buildings.

;

;