As laboratory and medical imaging equipment become ever more sensitive, the design of spaces that house them must also evolve.

Over the past decade, we’ve seen a clear trend in imaging equipment, like MRI machines and electron microscopes, demanding more and more from the spaces they are housed in. As advances in technology allow for greater image resolution, from brain scans to visualizing individual atoms of materials, the need to minimize disturbances such as vibration, electromagnetic interference (EMI), and acoustic noise becomes even more fundamental to design.

The rise in low-noise requirements coincides with increasing demand for medical and laboratory facilities to be located in busy urban environments, bringing highly sensitive equipment closer to troublesome noise sources such as road and rail traffic.

As designers, we must adapt our approach to meet these challenges and deliver spaces that allow current and future equipment to fulfill their imaging potential, all while remaining conscious of cost implications and broader project sustainability goals.

Quantitative design

Together, physical measurements and numerical analysis are a powerful tool for designing high-performing environments. Take, for example, a recent project at the University of Manchester, which involved housing some of the world’s most sensitive electron microscopes in a new city center campus development.

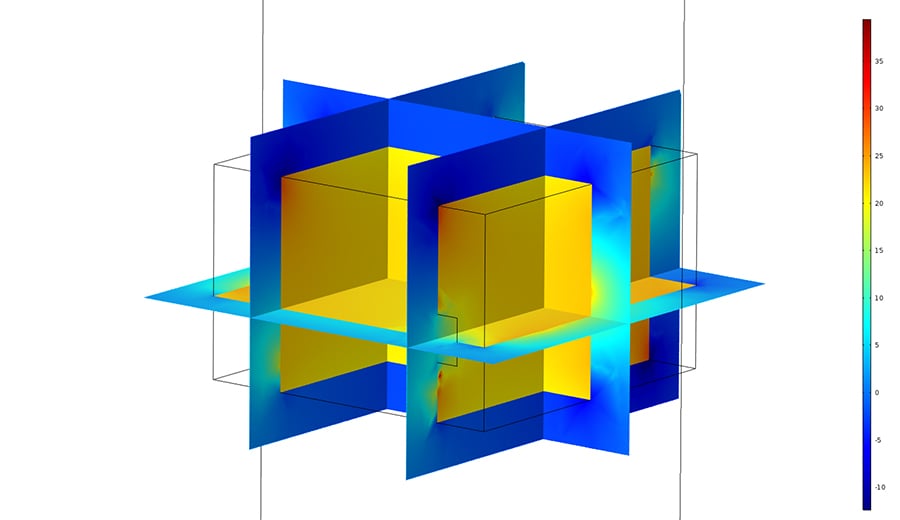

Minimizing the transfer of ground-born vibration through the foundation was a key challenge. Historical precedent and rules of thumb would have suggested the use of a very thick concrete foundation slab. However, using a combination of site measurements and finite element analysis to model the transmission of vibration through the ground and foundation, we demonstrated that a much thinner foundation slab could be used with virtually no reduction in performance. This led to significant savings in concrete, cost, and carbon.

Measurements can also play a vital role in developing our understanding of how spaces work after construction. Improvements in sensor technology and cloud computing have made it easier than ever to continuously measure the performance of a space and view real-time data. In addition to helping equipment users identify and troubleshoot sources of noise, these measurements provide important feedback to our design processes and assumptions. For example, measurements of vibration response in finished buildings have helped us improve our numerical modelling assumptions at the design stage.

Early involvement

While measuring and monitoring can provide invaluable insights when applied to existing environments, it’s often in the early planning stages that specialist acoustic, vibration, and EMI consultants can deliver the most value to a project. Taking noise sources, equipment adjacencies, and space planning into consideration at the start of a project can reduce the need for expensive design changes and costly mitigation in later stages, as well as influence design efficiencies for potential cost and sustainability savings.

For example, early analysis can be used to identify optimal locations to house sensitive equipment in a proposed development, which alleviates the need for costly design interventions to mitigate sources of vibration, EMI, or acoustic disruption.

As is often the case, a few hours from an expert early in a project can prevent significant headaches in later stages.

Magnetic field contour plot overlaid on architectural plans to help identify optimal locations for sensitive equipment.

Holistic design

Given the importance of expert input in early stages, it’s clear the design of high-performing environments requires intense coordination within a wider design team, as different performance objectives frequently lead to conflicting demands. What works for reducing vibration may be counterproductive to controlling magnetic fields. The optimal solution for acoustics may make achieving air flow and temperature requirements virtually impossible.

Innovative solutions are required to deliver spaces that meet equipment and users’ needs. But such innovation is only possible with good collaboration among equipment users, specialist consultants, architects, planners, and equipment manufacturers.

While designing the laboratories of the future might seem a far cry from the iconic Sydney Opera Houses or Centre Pompidous of Arup’s past, the same philosophy of total design that made those innovative buildings possible is perhaps even more essential today. As we tackle the complex technology, sustainability, and efficiency challenges facing the future —laboratories will undoubtedly play a vital role.

Interested in reading more about designing for low-vibration spaces? Check out our more detailed paper published by the Institution of Structural Engineers.

;

;