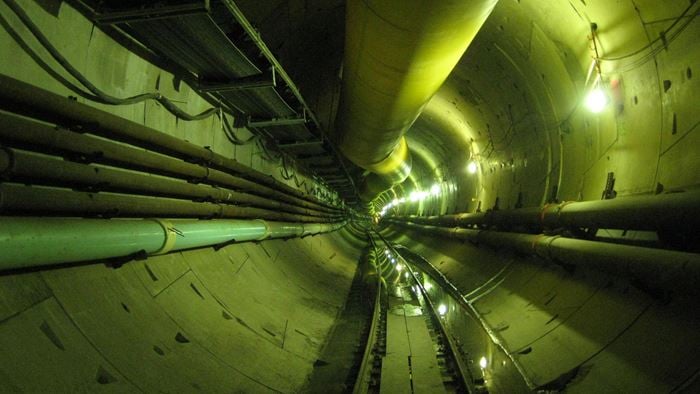

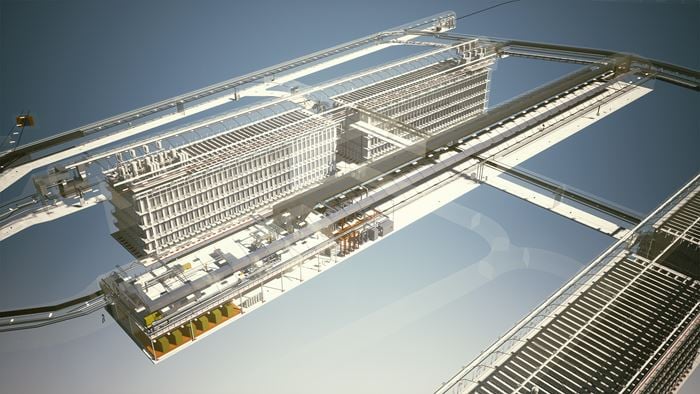

Arup has been working with resources company BHP to bring Saskatchewan’s Jansen Mine Project to life. By leveraging cutting-edge technology and collaborating across disciplines, the Arup team has helped BHP devise innovative, beyond-code solutions for this ambitious project, which marks the first instance of mechanized shaft sinking in the world and entails artificial ground freezing to a depth of 700m. The ground freezing technique helps to stabilize soil and prevents it from collapsing next to excavations.

The Jansen Project is set to be one of the largest potash producing mines in the world. When it reaches full capacity, the mine will produce an estimated eight million tons of potash annually, providing a rich store of nutrients to help agriculturalists keep soil fertile and maximize food production. As growing populations place higher demands on land and farms globally, the potash fertilizer industry supports the United Nations sustainable development goal to ensure food security and promote sustainable agriculture.

Arup has been involved in the Jansen Project since 2012, first serving in an advisory capacity before being appointed Engineer of Record for the rock excavation and design of the permanent shaft lining. As the Engineer of Record, the Arup team looked beyond traditional mining practices, harnessing insights from a broad cross-section of in-house experts, advanced modeling, and digital tools to help BHP tackle challenging ground conditions, optimize the artificial ground freezing process, and sink the watertight shafts to a depth of 1,000m.

Project Summary

One of the largest potash mines in the world

Engineer of Recordon the project

700mdepth of artificial ground freezing

Unique challenges, unique solutions

The Jansen Project involved construction of the shaft liner within an artificially frozen ground mass. The team took an unorthodox but highly effective approach. Noting the parallels between the mine’s concrete shaft and an ocean platform pedestal—both of which must withstand extremely high levels of water pressure—the team consulted with Arup’s offshore infrastructure experts to identify the best approach. In the end, the team developed a first-of-its-kind solution for the liner structure that uses watertight flexible joints and weak shearing backfill material to accommodate the anticipated thaw settlement movements once the freeze is decommissioned.

Arup looked beyond traditional mining industry practices for approaches to other problems as well. By integrating fracture propagation mechanics, a discipline not typically used in the mining arena, and introducing web-based site monitoring, our experts gave BHP and their shareholders the confidence to press on through extremely challenging ground conditions to successfully complete the shaft sink.

The Jansen Project is now well on its way to completion, with twin shafts reaching bottom depths of 1005m in 2018. It is currently slated for completion in winter 2021.

;

;