Station engineering design presents a unique range of engineering challenges, from establishing rigorous fire safety to creating high performance but sustainable mechanical, electrical and plumbing (MEP) and ventilation systems, and the need to make new platforms and tunnels connect seamlessly with existing stations.

Arup carried out technical design engineering on a number of the Elizabeth line’s new stations, working in joint venture with Atkins to design Tottenham Court Road, Custom House and Woolwich stations. Separate from the joint venture, we designed Canary Wharf Elizabeth line station for Canary Wharf Contractors Ltd and worked with Laing O’Rourke on Liverpool Street and Bond Street for the fit-out design.

Designing a station for below and above the water line

Canary Wharf was an unusual station in every way. The first station of the new line to be completed, it was constructed in the North Dock, surrounded by water and most of the station fully submerged with four levels of retail, restaurants and other amenities above the waterline as part of its over-site development.

The initial plan was to drain the entire 200 year old dock but that presented too much risk of environmental damage, huge costs and the risk of dock wall failure. Given the station would be built right beside the headquarters of major financial institutions like the FCA, HSBC, Morgan Stanley, Barclays, et al., noise and vibration were important considerations during construction so it would not impact the neighbours of the new station.

In a UK first at the time, our team used the Japanese Giken Piling system, which offers a clever system of interlocking steel tubes to create a watertight perimeter wall, whilst being almost silent in operation. Over five weeks, approximately 98 million litres of water were drained so the station could be built safely inside the walls.

We also reorientated the tunnel ventilation fans at the station. At the size of jet engines, moving them into a vertical position at each end of the station optimised space, allowing more room for station operations and retail. This design choice made the overall station box smaller, contributing to a reduction in costs from about £860m down to £500m, and a reduction in the programme by 12 months for this part of the scope, in time for tunnelling work to commence.

Smart ventilation design

When adding new facilities, platforms and services to an existing station, we often aim to adopt a ‘less is more’ MEP strategy – lower use of powered ventilation for example, can ensure the station is commercially and sustainably operable. With this ethos in mind, we designed the ventilation at Liverpool Street station’s new Elizabeth line facilities to be passive, bringing in naturally cool London air to provide 75% of its cooling per year, with electrical chillers only required to cope when temperatures are above a certain threshold. This lower cost, lower emission approach has been emulated wherever possible on the other Elizabeth line stations.

A tight squeeze

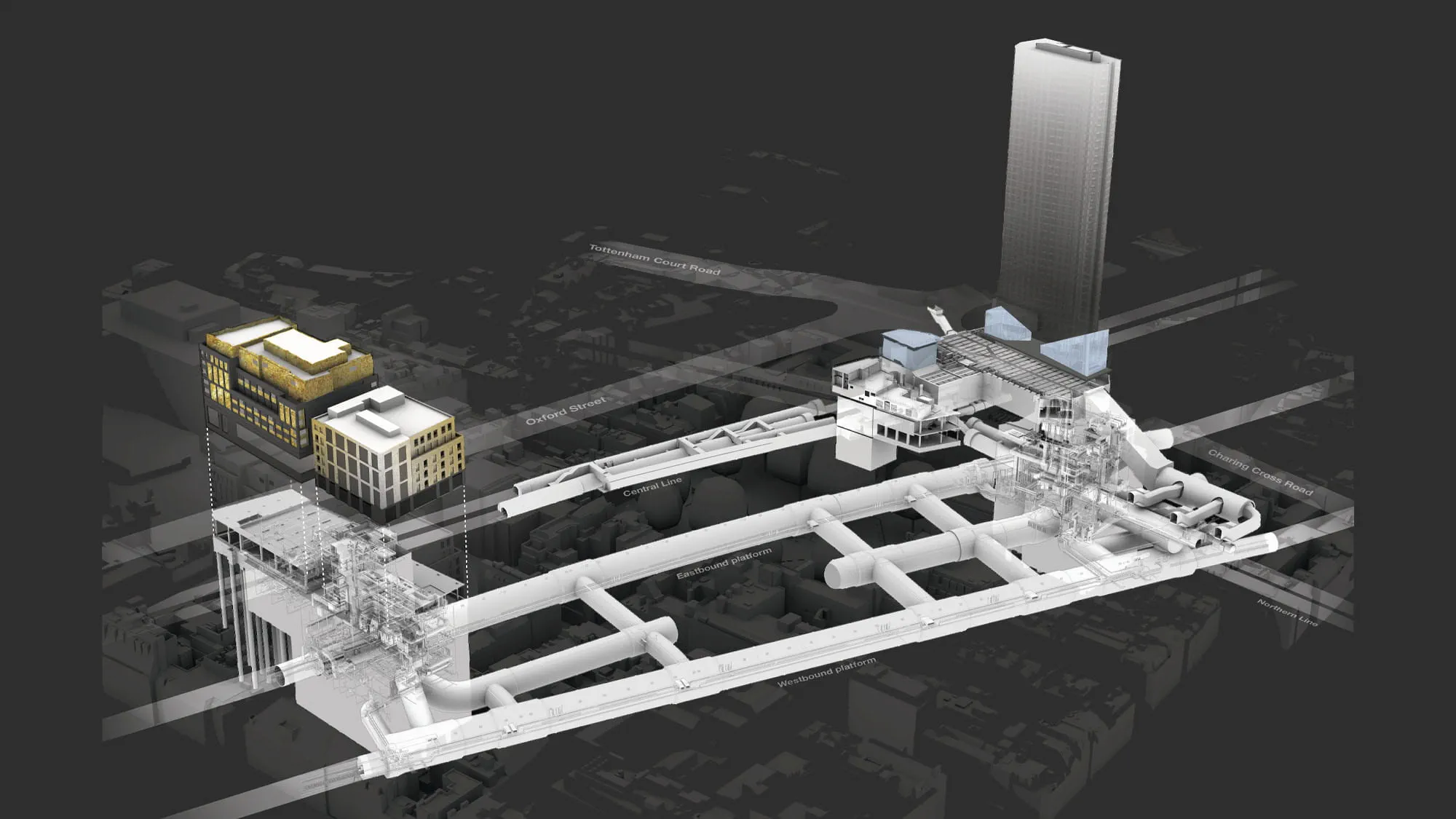

Expanding Tottenham Court Road station, already a complex, multi-line interchange on the tube network, to accommodate the new line was a major undertaking and the construction of declines to accommodate the escalators was a significant challenge. The top of these tunnels would have been close to listed buildings within water bearing gravel – a difficult challenge to overcome, typically requiring freezing the adjacent ground.

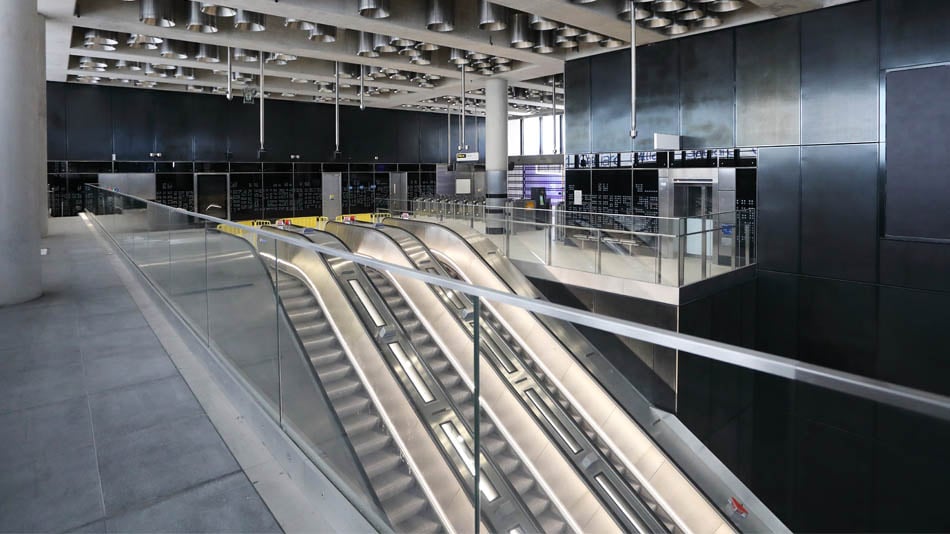

A breakthrough came when TfL agreed to remove the requirement for a direct link to the Central line from the Dean Street ticket hall, which meant we only needed a single flight of escalators that could just fit within the footprint of the station box. This eliminated the need for risky tunnelling activity, using an efficient construction methodology to deliver the escalators – now the third-longest on the whole underground network.

We had also recommended that the entrance for the line should be on a pedestrianised Dean Street, not discharging directly onto the busy footpath along Oxford Street, which would have removed extraordinarily valuable retail frontage while causing congestion for pedestrians and passengers. Bringing a major new station entrance to a Soho side street required a careful study to ensure a safe movement and flow of people across the service’s daily operation, in and out of the adjoining streets, but Westminster City Council were persuaded of the benefits and gave their blessing to this new arrangement.

Connecting people and places across London

Arup’s work on many of the Elizabeth line’s new stations has helped enable construction at Canary Wharf without disturbing residents, improve the passenger experience at Tottenham Court Road and lower emissions at Liverpool Street and many of the central Elizabeth line stations. Our work has extended beyond station operations to the design of mixed-use over-site developments above Tottenham Court Road, Bond Street and Canary Wharf stations, including specialist services such as acoustic consulting, vibration engineering and sustainability consulting.

;

;