Designed by Pritzker-prize winning architects Renzo Piano Building Workshop (RPBW), the Krause Gateway Center in Des Moines, Iowa is the new corporate headquarters of the Krause Group, a family of businesses best known for Kum & Go, a large chain of convenience stores.

The Krause Group subscribes to a sustainability framework that seeks to balance the needs of “People, Planet and Profit.” This commitment to sustainability has led the company to attain LEED-certification for 100 Kum & Go stores throughout the Midwest. They set the same goal for the Krause Gateway Center. For this project, the client aimed to use the power of good design to promote a more open and collaborative corporate culture, and to bring value to the community by creating a building that was a worthy addition to Des Moines’ architectural legacy.

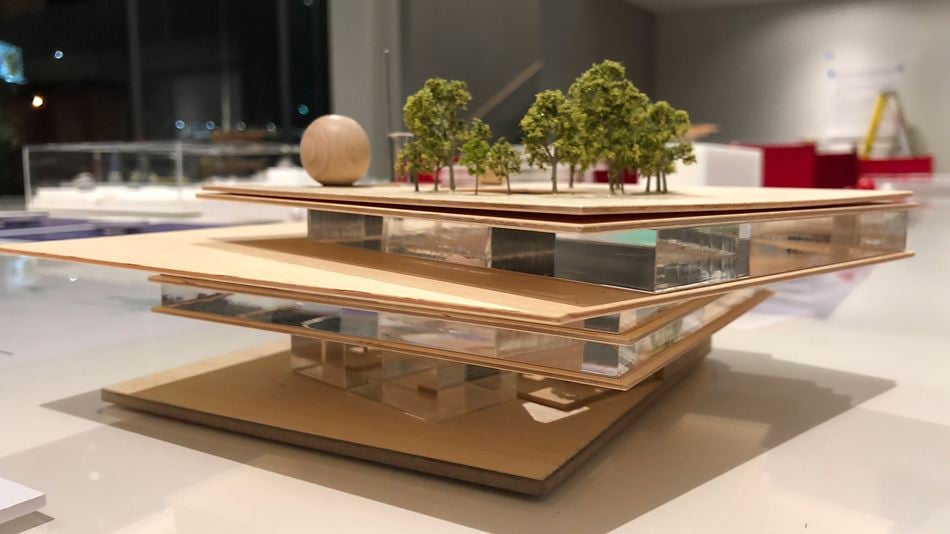

Arup worked closely with the architect and design team to develop a daylighting scheme for the building and acoustics and lighting strategies for its flexible, collaborative work spaces that maximized comfort and resource efficiency and helped the client qualify for LEED certification. The end result is a strikingly modern, sustainable building with a transparent structure that offers clear views of Western Gateway Park and the Pappajohn Sculpture Park.

The Krause Gateway Center design team embraced a philosophy of “total experiential design,” and developed an array of architectural and design strategies that work to subtly shape the experience of visitors and staff. Lightness, simplicity and openness were key drivers of the design. Arup worked closely with fellow members of the design team to devise customized lighting and acoustics solutions that supported the client’s vision and long terms goals, while providing the proper levels of functionality and flexibility.

Optimizing daylighting without compromising comfort and efficiency

Preserving an open, airy feeling in the building’s office spaces was key to promoting stronger connections among the client’s 800 staff members. This meant that Arup’s daylighting scheme had to balance the desire to provide users with clear, unimpeded views with the need to reduce glare and heat. To accomplish these goals, lead lighting designer Brian Stacy advised the architect on the design of the exterior’s landscape and hardscape elements. This collaboration led to the development of a strategy that prioritized daylighting while keeping the high angle, direct summer sun off of the building’s vertical glazing to optimize energy use and ensure visual comfort.

Sound masking: a high performance, design-sensitive acoustics solution

Providing sufficient speech privacy is more challenging in an open layout office than in a traditional office. This was particularly true for the Krause Gateway building, where the open layout and increased ceiling height invoked change in the aural environment. To avoid detracting from the open layout design while still providing the requisite level of speech privacy, Arup’s acoustics team proposed a layered strategy with sound masking as the base — a system that uses loudspeakers placed discreetly throughout the open office space to reduce distraction and provide an increased level of speech privacy.

The client’s previous experience with sound masking left them unconvinced of its value. To demonstrate its capabilities alongside additional acoustic design strategies, the Arup SoundLab was utilised to illustrate the results of a robust acoustic model of the room. Anechoic people noise recordings commissioned by Arup as part of an internal research project were used to simulate a typical workplace dialogue and activity noise. These recordings allowed the simulation to change dynamically, increasing the accuracy of the experiential auralization in the Arup SoundLab. The auralization also allowed Arup to demonstrate sound masking’s ability to effectively improve speech privacy in the open plan office. The completed building features two levels of sound masking solutions developed by Arup.

Designing future-proofed digital lighting infrastructure

A resilient building is inherently a sustainable building and the client wanted the Krause Gateway Center built to last at least 100 years. This meant that building systems needed to be flexible enough to adapt to changing business needs over time.

Arup’s lighting strategy for the headquarters anticipates rapid changes in lighting protocols over the next two decades. The team went back to first principles to design a flexible digital infrastructure system that can be easily upgraded as lighting digitization advances. This future-proofed system features a fully digital control signal that allows lighting components to “speak” to one another. It also collects data that can be used to make the building smarter.

The Krause Gateway Center project was the lighting team’s first opportunity to deploy an in house lighting automation tool that has now become standard on projects throughout the Americas region. The bespoke tool allows Revit to automatically generate lighting specifications based on lighting fixture information input into a model — an advancement that increases efficiency and aids in quality control.

Total design brings added value

Because Arup’s engineers and consultants take a holistic approach to design, our team also advised on strategies to achieve LEED credits. A unique pilot credit was achieved by collaborating with the project mechanical engineer and design team to select low noise mechanical plant equipment and locate it at ground-level with a barrier around it — rather than on top of the roof — to obtain an additional LEED point.

;

;