In the early 1990s Arup was commissioned for the design of Toyota’s Motor Manufacturing plant south-east of Istanbul. Our scope included engineering and architectural services.

The design was severely tested during the September 1999 Izmit earthquake that reached 7.8 on the Richter scale. The plant is located so close to the fault line that the surface rupture appeared along the boundary of the property.

No damage following earthquake

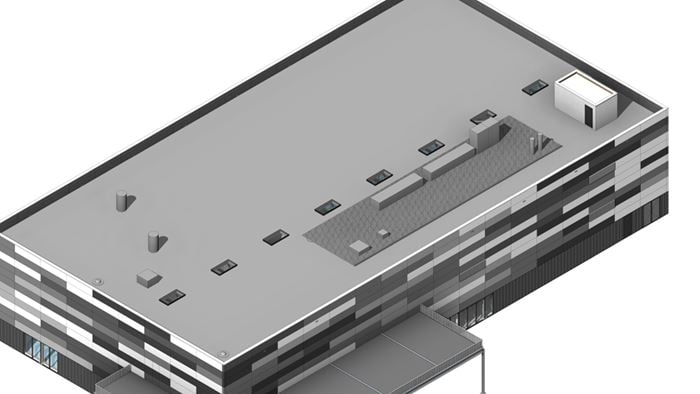

No significant damage was found in the structures after the earthquake. Our original design for the 140,000m² plant, producing over 100,000 cars per year, has been extended over the years allowing Toyota to increase production.

Since the earthquake, we have continued providing all design services to Toyota, including architectural detail design. Since then, the factory area has been increased with additional extensions to the buildings. The total extension area is approximately 40,000m2.

Long history of collaboration

Toyota and Arup have a long history of working together. Arup produced mechanical, electrical, IT and communications system designs for the Toyota Headquarters for Technical Training in the UK, total facility design services for the construction of the 230,000m² automotive manufacturing and assembly plant for the company at Burnaston in the UK, and design and project management services for the 20,000m² logistics platform in Madrid, Spain.

Geotechnical investigation

Originally, Arup’s scope of services did not include geotechnical engineering. The client had already initiated a full scale geotechnical survey on site before purchasing the land. Arup's structural design was based the results of this survey.

During the structural design the Arup team was concerned about the North Anatolian Fault Line passing about 6km south of the factory site. This fault line was analysed using NASA remote satellite imaging, likely a first for such projects in Türkiye at that time.

The analysis revealed that a fault line from the main fault was traversing the factory site. The alluvial soil made the identification of this fault by the previous conventional geotechnical surveys impossible. The entire structural and foundation systems of the plant were modified and factory footprint shifted to counter the effects.

;

;