The Westmead Institute for Medical Research (WIMR) is a leading Australian medical research institute making breakthrough discoveries into some of the most serious diseases of our time. The work of 11 research centres at WIMR focuses on five key themes: cancer, cardio-respiratory, infection and immunity, liver and metabolic, and neuroscience and vision. This ten-storey, state-of-the-art building is a key facility in the world-leading Westmead Health and Education Precinct.

The location of the building facilitates close collaboration with Westmead Hospital and other research organisations nearby.

The laboratories are linked by a central staircase that also connects offices, meeting rooms and communal spaces, allowing researchers to meet and work together. The atrium and open spaces provide visibility across floors, enabling people to feel part of the building’s research community.

Bringing natural light into the communal spaces and filtered light into the laboratories was a key component of the brief to encourage interaction and collaboration amongst scientists. Scientific research spaces that can accommodate natural light are unusual as external stimuli may affect experiments. This element required significant planning and collaboration with researchers to ensure the environments are both effective and scientifically sound. We designed the mechanical systems to support a modern ‘lifestyle’ interior office design.

In non-laboratory spaces, Arup engineered full-height glass windows to bring daylight inside, while the façade’s louvres block out heat and glare. Double-glazed windows improve energy efficiency and minimise noise, providing comfortable, light-filled spaces for work and recreation.

The building was designed in conjunction with the researchers to ensure it is both practical and an enjoyable space to work in.

Project Summary

$110million project

11research centres

17,500sqmlaboratory and office spaces

Flexibility for the future

Arup brought an innovative solution to the client – a manifolded fume exhaust system – that would replace the (then) Australian Standard requirement for each fume cupboard to have its own exhaust duct and fan. The manifolded system exhausts vapours from the fume cupboards collectively, cutting operational costs such as the number of components, a reduction in the replacement of components, and the flexibility of moving fume cupboards or adjusting their quantity.

We worked with our global colleagues who have extensive experience with the standard international practice for manifolded systems, including operating examples in similar buildings around the world.

This experience, coupled with our willingness to certify the design as an alternative solution, gave the client confidence to adopt this system.

“The WIMR building is a beautiful, spacious, well-lit environment, and this helps to attract the best scientists and students to our Institute. It was designed from the inside out by architects and project managers, working closely with our teams of scientists to achieve a purpose-built environment. It has achieved its aim of enhancing collaborations between scientists and students, resulting in new directions for our research that aims to improve the health and lives of all Australians. ” Professor Tony Cunningham AO Executive Director, WIMR

Saving energy and improving safety

A key component of our mechanical engineering is the air-quality sensing system to monitor vapours in the laboratories. The demand-control ventilation system collects and analyses air samples for Volatile Organic Compounds and other pollutants. If the air quality is adequate, the air change rate per hour is reduced, lowering fan use and greatly reducing the heating and cooling of outside air as it passes through the air distribution centre of a heating, ventilation and air conditioning (HVAC) system.

Making open spaces fire-safe

Our fire safety engineers worked closely with the architect in developing design options to suit the laboratory and ancillary spaces, including integrating the manifolded fume exhaust systems.

In addition, we fire engineered the unenclosed spaces of the central atrium and connected floors. This required advanced knowledge of fire behaviour and the vulnerabilities of the atrium floor.

Ultra-secure containment spaces

The institute houses Physical Containment Level 2 (PC2) wet laboratories, Physical Containment Level 3 (PC3) facilities and IS0 7 certified cleanrooms.

PC2 and PC3 facilities are designed to contain micro-organisms to protect workers, the surroundings and the environment from contamination. PC3 facilities handle infectious organisms that cause serious harm such as Human Immunodeficiency Virus-1 (HIV-1) and Simian Immunodeficiency Virus.

These types of structures are essentially an impervious cool-room box-type construction and stabilising the interior environment is carried out from the outside perimeter. Our mechanical engineers led the multidisciplinary team of specialists to design systems to build and maintain these sterile rooms.

“It’s rewarding seeing our contribution to this project create a modern, more connected workspace for scientists. The fact that there’s daylight permeating write-up rooms, laboratories and an open atrium connecting floors brings a new style of collaboration to the Institute. ”

Julian Soper Principal | Health – Australasia Leader

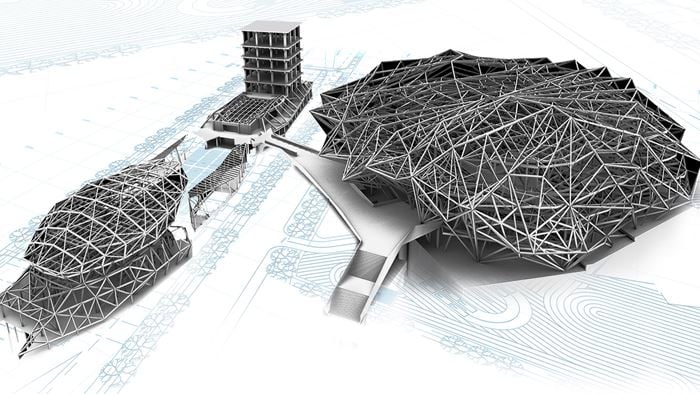

Advanced application of BIM software

We increased project design efficiencies by adopting one of the first building information modelling (BIM) software systems that included multiple disciplines. Mechanical, electrical and medical gas disciplines were all in the one model which created significant time savings and improved coordination.

We were able to develop new tools in the model in conjunction with the architect. Room data sheets were created virtually: these allowed us to add information to the rooms which was reflected on the architect’s room data sheets, reducing proof reading time.

Our work contributed to WIMR receiving the Sir John Sulman Medal for Public Architecture in 2015.

All images © Carl Drury

;

;