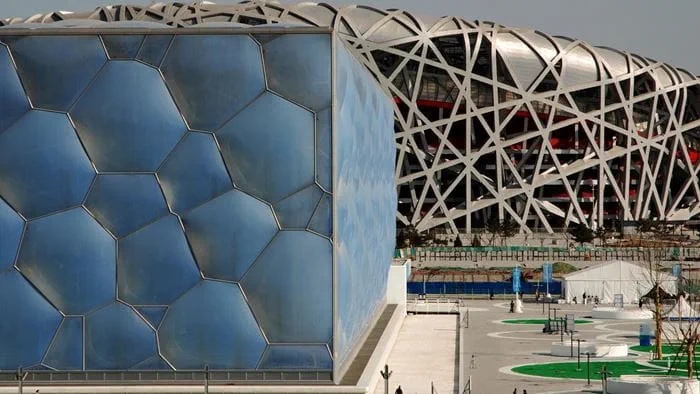

Lying alongside the Suzhou Creek and the M50 Moganshan Road Art District, Tian An 1000 Trees is a mega integrated project, envisioned to revitalise the heritage site of the Shanghai Flour Mills. Designed by architect Thomas Heatherwick, the two-stage development comprises a total above ground GFA of 300,000m².

As its first phase, the recently opened ‘1000 Trees’ shopping mall is covered with greenery cascading over each level to resemble a mountain, creating an iconic urban oasis in Shanghai. The second phase, which incorporates office, hotel, retail and cultural space, is currently under construction.

Arup has provided design and structural engineering services for this project since 2012, in a joint team effort by the London and Shanghai offices. We also offered structural solutions for the two-storey steel pedestrian bridge which connects the first and second phase of the development.

Project Summary

300,000m² total above ground GFA

260mlong continuous frame without movement joints in phase 1

1,000trees adorning the building

Interior view © Kingkay Architectural Photography

A well-thought-out structural solution

The building’s architectural form posed complexities and challenges to structural design and construction. The architect’s original intent was to use a logical structural approach by adopting an efficient structural moment frame system with 9m x 9m column grids. However, the mall’s interior layout contains various spatial irregularities and requirements such as circulation areas, atria, event spaces and the shop dimensions, meaning that not all the columns were able to align with the 9m-grid logic.

Following careful consideration and communication with the stakeholders, we developed a solution to fulfil the spatial requirements using different mechanisms, including shifting columns off the 9m grid, tilting columns and column transfers as well as incorporating long-spans, cantilever structures and hanging columns.

A slender building without movement joints

The building is long and slender on plan, with the length to width ratio of the narrowest floor being 12:1. The structural framing at certain floors was, inevitably, reduced to single moment frame action. In addition, the receding building edge occurs on three out of the four elevations and is shaped as serrated balconies at 45 degrees.

To optimise the global stability framing and maximise the headroom, we focused on reinforcing the building seismic performance, including period, building drift and relative rotation, while addressing the long and narrow building shape and the cascading effect of receding façade. This resulted in an innovative, 260m long continuous frame without movement joints.

A novel approach to column design

All columns at the building perimeter and void edges are pushed out of frame, each topped with tree pots, so they can be exposed and visually standalone. The beam moment framing at these locations was offset and eccentric to the columns, connected by shear stubs only. These details were not conducive to seismic performance and had greater buckling tendency.

On the other hand, the design required the exposed columns to be rotated at 45 degrees to the moment beam orthogonal grid, which led to a cumbersome reinforcement connection at the beam/column head location. To address the situation, we devised a simple yet effective solution by adopting a circular structural column and constructing it with additional flaring to form the 45-degree effect.

Tree pots – close-up view of fair-faced concrete © Kingkay Architectural Photography

Tree pots: the key visual element

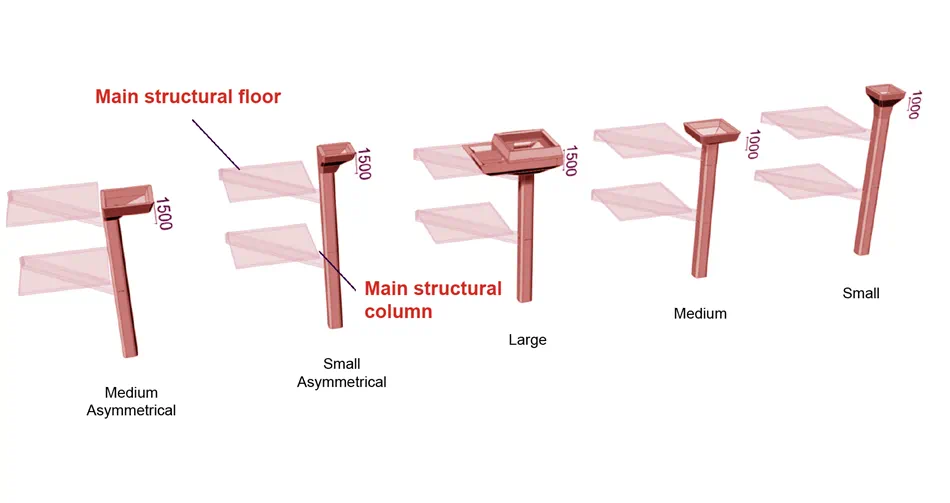

One of the visual highlights is the 1,000 trees adorning the building. Although the tree pots do not form the building structural system, they were an important part of the design and detailing for construction.

We considered various materials including steel, precast and GFRC in constructing the tree pots. Ultimately, reinforced fair-faced concrete was adopted, and the pots were divided into different prototypes for modularity and ease of construction. The formwork was designed to be reusable with each pot having up to eight castings.

;

;