The Sydney Opera House is one of the world’s most famous buildings and its history is deeply interconnected with our own.

In the mid-1950’s Bennelong Point, known to the Traditional Owners as Tubowgule, set between Sydney Harbour and the Sydney Botanic Gardens, was chosen as the site for Sydney’s new arts and culture building. Danish architect Jørn Utzon won the international design competition for the Sydney Opera House design.

In 1957, we were appointed as the project’s consulting engineers and our founder, Sir Ove Arup, travelled to Australia to set up a site office, establishing our Australian practice.

From start to completion, we provided structural engineering for all elements of the building, including the foundation, the roof’s iconic pre-cast shells, the concourse and glass walls.

The Opera House’s complex design presented a unique opportunity for close collaboration between engineering and architecture. It also pushed engineering boundaries, creating technical innovation and establishing design conventions we still use today.

Project Summary

1,056,006 ceramic tiles cover the Opera House roof

12trial schemes for the iconic sail design

1957the start of our work on the Opera House

A unique collaboration between engineering and architecture

The Opera House was, at the time considered unbuildable. This complexity created a unique opportunity for Sir Ove Arup and architect Jørn Utzon to collaborate closely – a break from conventional architectural practice at the time.

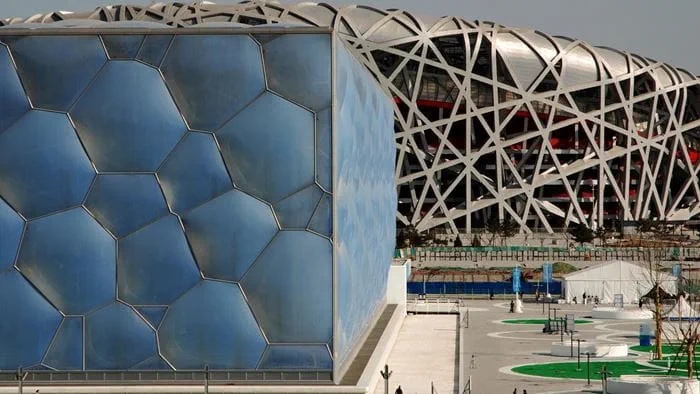

The crowning achievement of this collaboration is the Opera House’s most recognisable design component, the concrete roof sails, which hold 1,056,006 ceramic tiles. There was no precedent anywhere is the world for building the sails, which needed to be self-supporting.

Working together, they created 12 trial schemes before landing on a spherical solution consisting of ten roof sails built from segments of the same sphere, 75 metres in diameter. Each sail is made from pre-cast concrete supported by concrete ribs. The simplicity of this solution enabled the ribs to be mass produced on site and then lifted into place, offering design coherence and economies of scale.

Pushing the boundaries of materials and technology

The Opera House epitomises the late 20th century’s daring use of modern concrete design and construction techniques. The building is famous for its innovative use of exposed structural concrete as a key architectural feature.

The concourse, which provides pedestrian and vehicle access to the building, is the most notable feature of the building’s concrete base. Ove Arup designed folded pre-stressed concrete beams to support the base structure. By integrating the techniques of folded plate structures and prestressing, he enabled the creation of expansive open spaces inside the podium, such as the Box Office Foyer, without the need for structural columns.

The wind loads for the sail’s curved surfaces were unknown and had to be determined. Our team pioneered the use of wind tunnel testing for buildings which is now common practice in design for large buildings all over the world.

The Opera House’s glass walls enclose the openings between the roof sails and the podium structure. Laminated glass was chosen for its toughness and ability to be shaped on site, yet little was known about its use for architectural design. Our team undertook a research programme to understand the structural behaviour of architectural laminates. Equipped with this knowledge, we designed the first large-scale example of using glass as a structural load bearing material in a building.

.

© Hamilton Lund

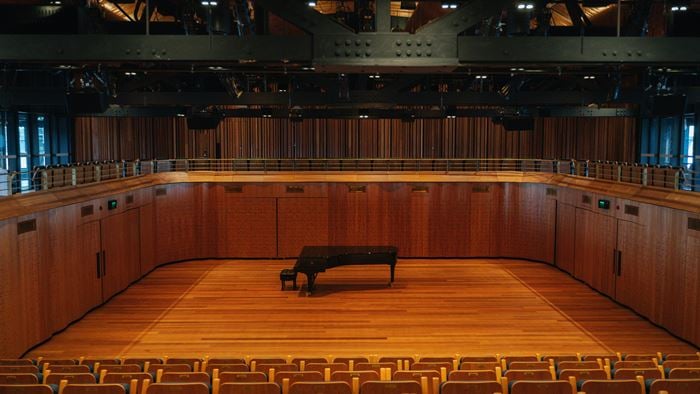

Preserving and evolving the Sydney Opera House’s legacy

The structural engineering of the Opera House becomes increasingly more complex over time as it is progressively altered to accommodate modifications, upgrades and renewal projects, which are necessary to maintain the place as a functional public building and leading performing arts centre.

© Victor Caringal

From repairs and maintenance to major upgrades, our team continues Ove’s work preserving and evolving the Sydney Opera House for future generations of visitors, artists and performers so everyone can enjoy this global icon.

Arup is a proud sponsor of Sydney Opera House.

;

;